Maximum Measuring Accuracy

Linear ±0.000040″ (0.001 mm)

Repeatability ≤0.000040″ (0.001 mm)

Gage R & R ≤10% capability in close tolerance bores.

Contact Dyer with your application.

Electronic, Non-Tipping Automatic Centering & Aligning, Dedicated Size & Range

“You just drop the gage in the bore, take your hands off the gage and view the measurement reading.”

Fast, accurate measurement.

No operator error.

Easy to use.

High accuracy, 2-point gaging.

Shop-rugged 24-7 production gage.

Ideal for use in shallow, large bores.

Open Single Cross® design allows operator to view bore when measuring.

Tool steel RW 60-65.

Carbide contact points

1. Choose bore gage head based on Ø and type of bore being measured.

2. Choose a holder.

3. Choose an indicator.

4.Use a master ring or adjustable setting master

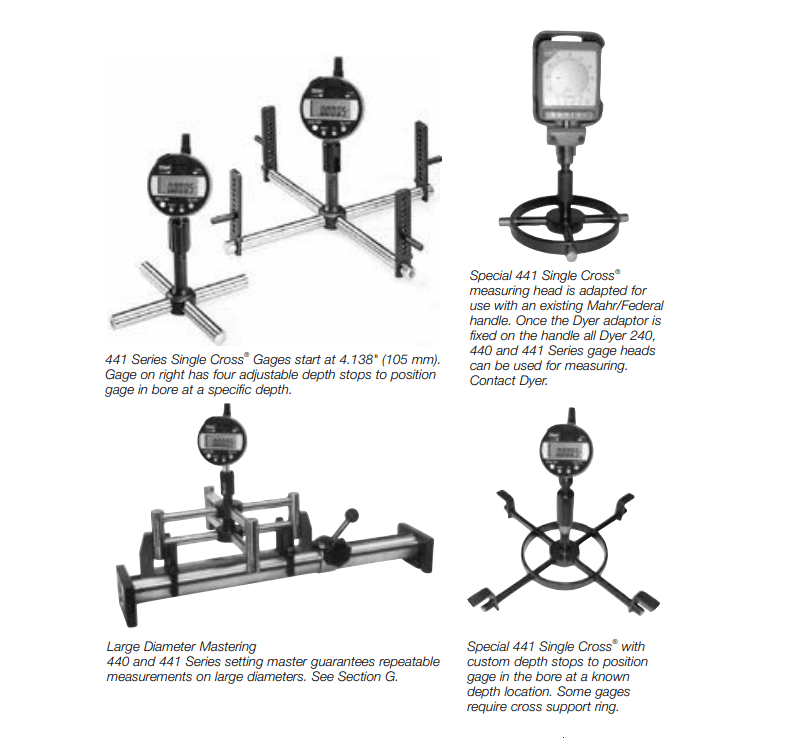

441 Single Cross® Measuring Heads

| Size Selection | Thru and Blind Hole Bores | Super Blind Hole Bores | |||

| Inch | mm | Tool Steel | “h” DIM | Tool Steel | “h” DIM |

| 4.138-4.331 | 105.1-110.0 | 441-105 | ALL

“h” DIM ARE 0.236” (6 mm) |

441-205 | ALL

“h” DIM ARE 0.118” (3 mm) |

| 4.332-4.724 | 110.1-120.0 | 441-110 | 441-210 | ||

| 4.725-5.118 | 120.1-130.0 | 441-115 | 441-215 | ||

| 5.119-5.512 | 130.1-140.0 | 441-120 | 441-220 | ||

| 5.513-5.906 | 140.1-150.0 | 441-125 | 441-225 | ||

| 5.907-6.299 | 150.1-160.0 | 441-130 | 441-230 | ||

| 6.300-6.693 | 160.1-170.0 | 441-135 | 441-235 | ||

| 6.694-7.087 | 170.1-180.0 | 441-140 | 441-240 | ||

| 7.088-7.480 | 180.1-190.0 | 441-145 | 441-245 | ||

| 7.481-7.874 | 190.1-200.0 | 441-150 | 441-250 | ||

| 7.875-11.811 | 200.1-300.0 | 441-155 | 441-255 | ||

| 11.812-19.690 | 300.1-500.0 | 441-160 | 441-260 | ||