Maximum Measuring Accuracy

Linear ≤ 0.00012″ (0.003 mm)

Repeatability ≤ 0.000040″ (0.001 mm)

Gage R & R capability ≤10% when

measuring high tolerance bores.

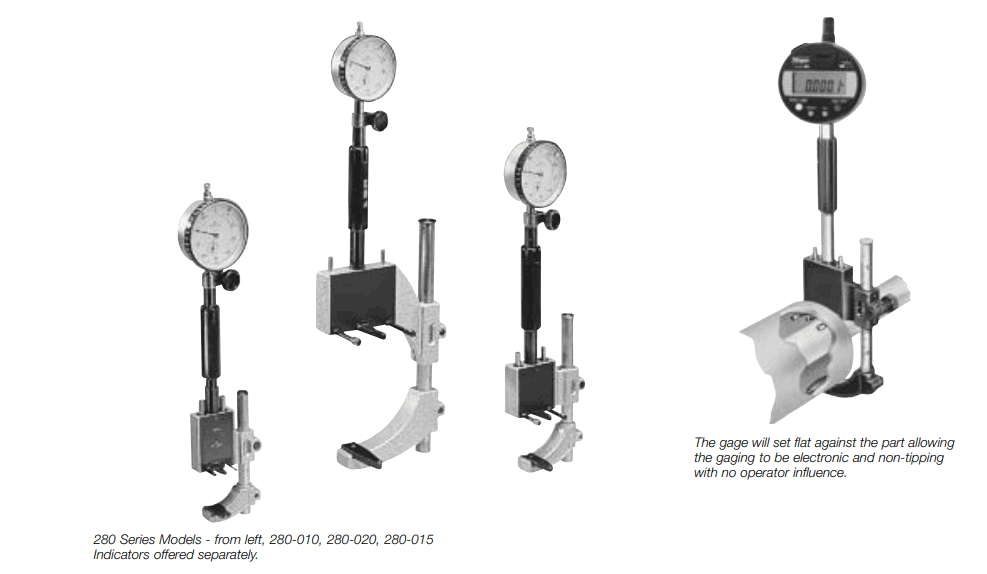

Easy to use 280 Series gages

Cut labor costs, reduce scrap. Fast accurate gaging on the machine with bore tooling in place. Spring-loaded 3-point centering and 2-point measuring. Placing the gage flat against the part allows for non-tipping, no operator influence gaging.

Notable Features

Time saving. Use on the manufacturing machine.

Large adjustable gage range and long contact point travel.

Shop-rugged, fast measurements.

Gage R & R capable, electronic indicator.

Customize standards. Contact Dyer with your application.

280 Series Models and Specifications

| Range

Inch (mm) |

Contact Point

Travel Inch (mm) |

Diameter B Max | Measuring Depth MT | Order No. |

| 1.00–2.75″ (25–70 mm) | 0.098″

(2.5 mm) |

0.236–1.772″ (6–45 mm) | 0.472″ (12mm) | 280-005 |

| 1.38–4.33″

(35–105 mm) |

0.118″

(3.0 mm) |

0.433–2.756″ (11–70 mm) | 0.709″ (18 mm) | 280-010 |

| 3.94–8.27″ (100–210 mm) | 0.138″

(3.5 mm) |

0.787”–5.118″ (20–130 mm) | 1.181″ (30 mm) | 280-015 |

| 3.94–11.02″

(100–280 mm) |

0.138″

(3.5 mm) |

0.787”–5.118″ (20–130 mm) | 1.181″ (30 mm) | 280-020 |

| 7.87–19.68″

(200–500 mm) |

0.138″

(3.5 mm) |

0.787–9.49″ (20–240 mm) | 1.181″ (30 mm) | 280-025 |