Maximum Measuring Accuracy

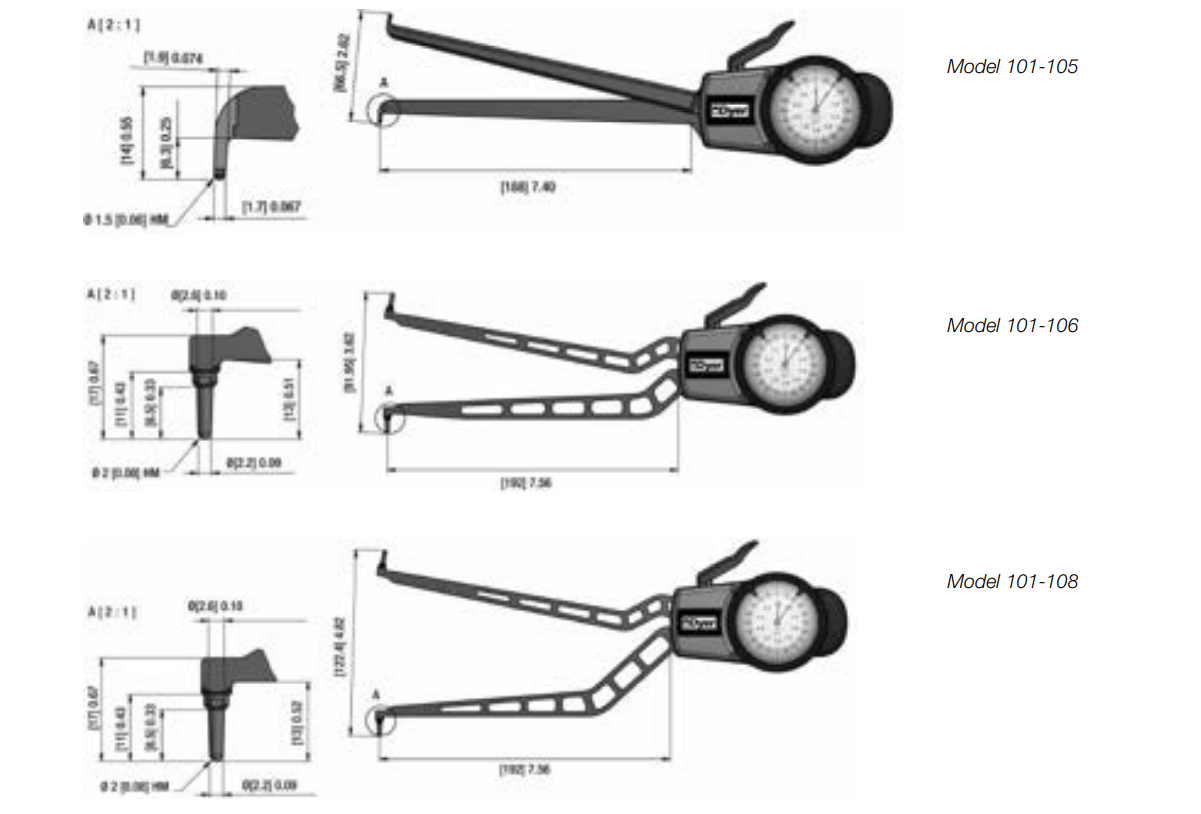

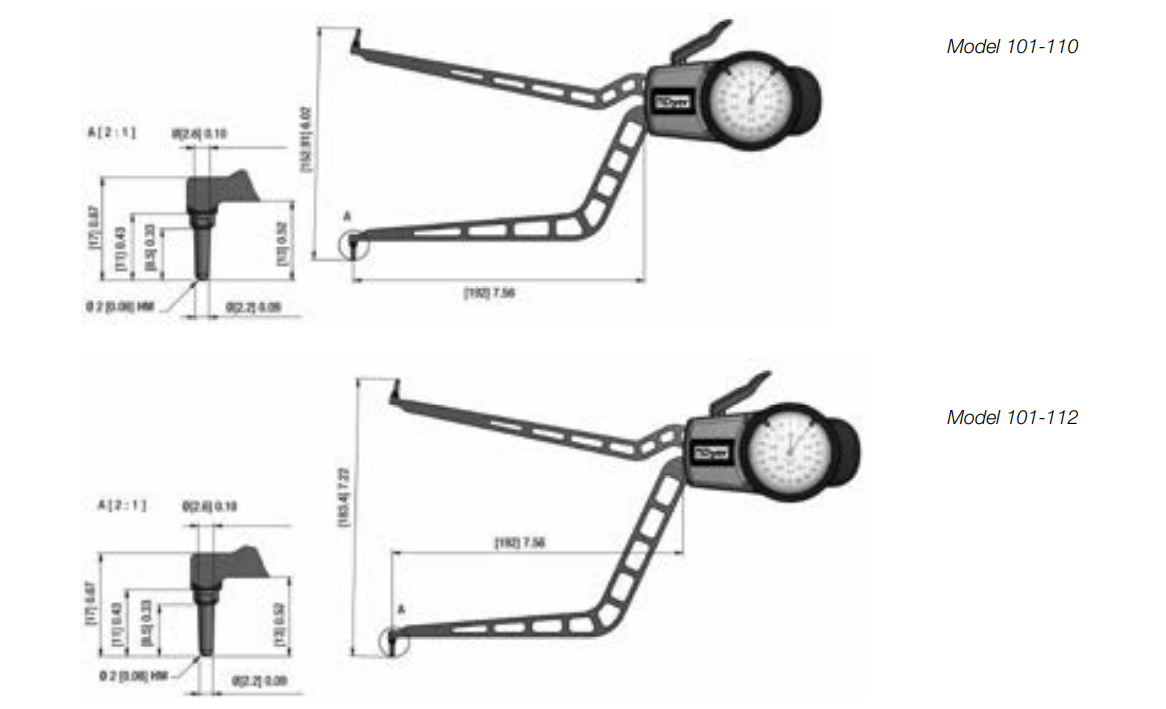

101 Series with 7.0″ reach

Linear Accuracy ± 0.002″ (0.050 mm)

Repeatability ± 0.001″ (0.025 mm)

Gage R & R capable

Notable Features

These gages are direct reading models.

Large range and contact travel.

Rugged, 24/7 shop use.

Special Carbide Ball Contacts

The carbide ball sizes shown below are in stock for immediate delivery. We also offer different types of material, i.e., chrome, ruby, ceramic, teflon. Additional customized sizes are available. Contact us with your application requirements.

101 Series Standard Specifications

| Range | Max

Contact Travel |

L Dim

Reach of Arms |

A Dim

Max Depth Groove |

B Dim

Min Width Groove |

Carbide Ball

Contact Standard Ø |

Graduation | Order

Number |

| Inch Specifications | |||||||

| 0.6–2.6″ | 2.0″ | 7.0″ | 0.177″ | 0.098″ | 0.059″ | 0.001″ | 101-105 |

| 1.6–3.6″ | 2.0″ | 7.0″ | 0.300″ | 0.098″ | 0.080″ | 0.001″ | 101-106 |

| 2.8–4.8″ | 2.0″ | 7.0″ | 0.300″ | 0.098″ | 0.080″ | 0.001″ | 101-108 |

| 4.0–6.0″ | 2.0″ | 7.0″ | 0.300″ | 0.098″ | 0.080″ | 0.001″ | 101-110 |

| 5.2–7.2″ | 2.0″ | 7.0″ | 0.300″ | 0.098″ | 0.080″ | 0.001″ | 101-112 |

| Metric Specifications | |||||||

| 15–65 | 50 mm | 180 mm | 6.3 mm | 2.5 mm | 1.5 mm | 0.05 mm | 101-207 |

| 40–90 | 50 mm | 180 mm | 8.0 mm | 2.5 mm | 2 mm | 0.05 mm | 101-208 |

| 70–120 | 50 mm | 180 mm | 8.0 mm | 2.5 mm | 2 mm | 0.05 mm | 101-210 |

| 100–150 | 50 mm | 180 mm | 8.0 mm | 2.5 mm | 2 mm | 0.05 mm | 101-212 |

| 130–180 | 50 mm | 180 mm | 8.0 mm | 2.5 mm | 2 mm | 0.05 mm | 101-214 |

Carbide Ball Contacts

| Inch | mm |

| 0.031 = 1/32 | 0.5 |

| 0.063 = 1/16 | 1.0 |

| 0.078 = 5/64 | 1.5 |

| 0.098 = 3/32 | 2.0 |

| 0.125 = 1/8 | 2.5 |

| 0.156 = 5/32 | 3.0 |

| 0.188 = 3/16 | 3.5 |

| 0.250 = 1/4 | 4.5 |

| 0.312 = 5/16 | 5.0 |

| 0.438 = 7/16 | 5.5 |

| 0.500 = 1/2 | 6.0 |

| 0.625 = 5/8 | 7.0 |