Maximum Measuring Accuracy

Linear Accuracy at 0.100″ Travel

± 0.0005″ (0.010 mm)

Full range ± 0.001″ (± 0.020 mm)

Repeatability ≤ 0.0005″ (≤ 0.010 mm)

Notable Features

Fast, accurate, repeatable.

Direct reading.

Spring-loaded contact arms.

Needle and ball contacts also available.

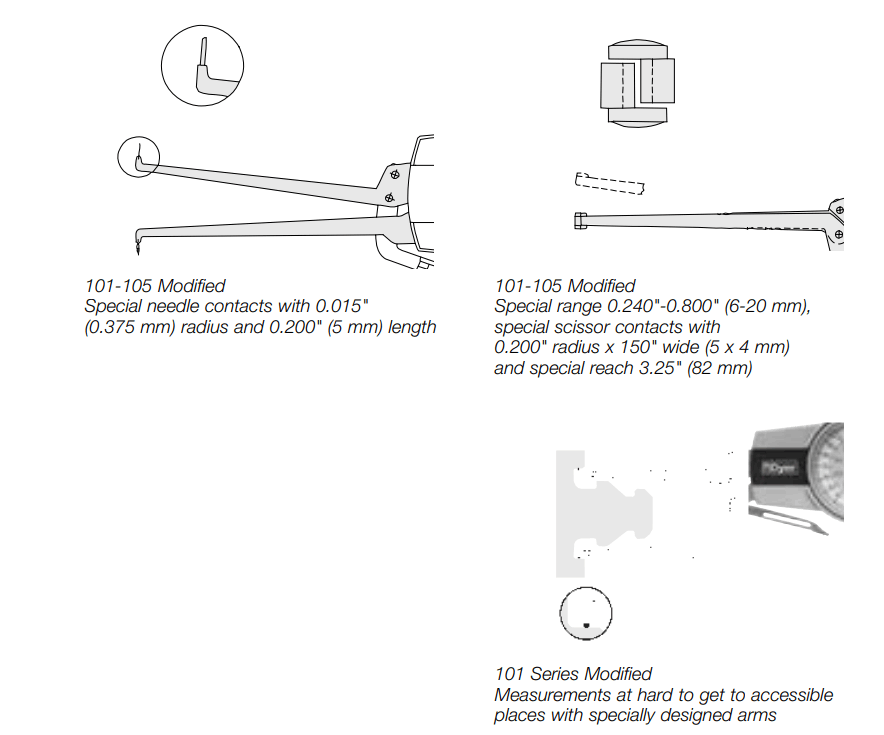

Customized Gages from

Standard Gage Models

Dyer will customize a standard “in-stock gage” to meet your part measuring needs. We can change ranges, arm sizes and lengths, add depth stops and modify contact point tips, ball sizes and types.

Special Gage Designs

(No Minimum Quantities)

Dyer will make a single gage to meet your requirements. We have a large number of special designs/gage solutions in our files. Contact our application engineers and show us your application requirements.

We can help you!

Special Carbide Ball Contacts

The carbide ball sizes shown below are in stock for immediate delivery. We also offer different types of material, i.e., chrome, ruby, ceramic, teflon. Additional customized sizes are available. Contact us with your application requirements.

| Inch | mm |

| 0.031 = 1/32 | 0.5 |

| 0.063 = 1/16 | 1.0 |

| 0.078 = 5/64 | 1.5 |

| 0.098 = 3/32 | 2.0 |

| 0.125 = 1/8 | 2.5 |

| 0.156 = 5/32 | 3.0 |

| 0.188 = 3/16 | 3.5 |

| 0.250 = 1/4 | 4.5 |

| 0.312 = 5/16 | 5.0 |

| 0.438 = 7/16 | 5.5 |

| 0.500 = 1/2 | 6.0 |

| 0.625 = 5/8 | 7.0 |