Light weight

Fast gaging

Ideal for shallow IDs and ODs,

counter bores, grooves, PD’s gears

Notable Features

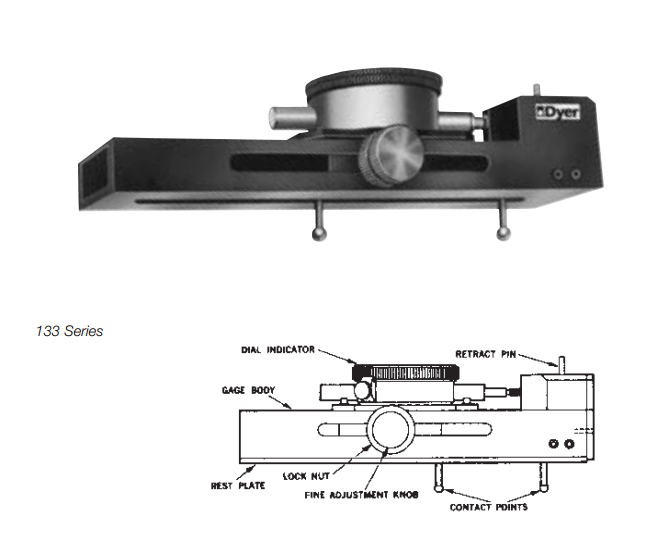

Reed transfer movement offers precise frictionless repeatability.

Fast, 2-point measurement directly across Ø.

Hardened A-2 gage resting surface.

Fine adjustment.

0–1″ adjustable gaging depth, contact points rotate greatly extending useful gaging life.

Fast acting fine adjustment setting, change over ID to OD in seconds.

How to Order

1. Select gage model

2. Select contact points

133 Series gage specifications

| ID Range | OD Range | Indicator Travel | Adj

Gaging Depth |

Length | Weight (oz) | Order No.

.0005″ Indicator |

Order No.

.0005″ Digital Indicator |

Order No.

.0001″ Indicator |

Order No.

.0001″ Digital Indicator |

| 0.44″–3.25″ | 0.03″–3.00″ | 0.025″ | 0–1.0″ | 4.50″ | 16 | 133-000 | 133-800 | 133-001 | 133-801 |

| 0.44″–5.50″ | 0.03″–5.19″ | 0.050″ | 0–1.0″ | 7.50″ | 22 | 133-002 | 133-802 | 133-003 | 133-803 |

| 0.44″–9.31″ | 0.03″–9.00″ | 0.050″ | 0–1.0″ | 11.38″ | 26 | 133-004 | 133-804 | 133-006 | 133-806 |

133 Series contact point information

| Order No. | Adj Gaging Depth | Contact Point Material | Contact Points |

| 133-005 | 0.0″–0.5″ | Hardened Steel | 5/32″ |

| 133-010 | 0.5″–1.0″ | 0.1875″ Dia. Hard. Steel | |

| 133-015 | 0.0″–0.5″ | 0.1875″ Dia. Carbide Ball | |

| 133-020 | 0.5″–1.0″ | 0.1875″ Dia. Carbide Ball | |

| 133-025 | 0.0″–0.5″ | 0.1875″ Dia. 1/2 Carbide Ball | |

| 133-030 | 0.5″–1.0″ | 0.1875″ Dia. 1/2 Carbide Ball | |

| 133-035 | 0.0″–0.5″ | 0.05″ x 0.50″ Disc Hard. Steel | |

| 133-040 | 0.5″–1.0″ | 0.05″ x 0.50″ Disc Hard. Steel | |

| 133-045 | 0.0″–0.5″ | Spec Carbide Ball | |

| 133-050 | 0.5″–1.0″ | Contact Office | |

| 133-055 | 0.0″–0.5″ | Hard. Steel 0.125″–0.500″ Dia. Taper | |

| 133-060 | 0.5″–1.0″ | Hard. Steel 0.125″–0.500″ Dia. Taper |