Maximum Measuring Accuracy

Linear ≤ ±0.000040″ (0.001 mm)

Repeatability ≤ ±0.000010″ (0.00025 mm)

Gage R & R capability ≤10%

Measuring high tolerance 0.0003″ (0.008 mm)

The world’s most accurate tipping bore gages.

Precision bore gages for ID’s from 0.18″ – 31.50″ (4.5 – 800 mm)

Notable Features

Oversize, retractable, spring-loaded centering base.

Special designed segment to transfer the measurement.

Invar steel handle for stability.

When tipping the gage thru the reversal point, the operator sees an exact, repeatable and clearly visible reading.

Customized models include optional chrome centering base and ruby contacts.

Models and Specifications

| Measuring

Range Inch (mm) |

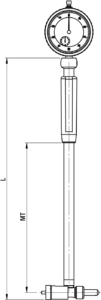

Short Handle

Measuring Depth “MT” |

Short

Handle Total Measuring Depth “L” |

Order No. Short Handle with Carbide

Contacts & Tool Steel Head |

Order No.

Short Handle with Ruby Contacts & Tool Steel Head |

Order No. Short Handle with Carbide Contacts &

Chrome Head |

| 0.18″–0.24″ (4.5–6) | 0.94″ | 0.94″ | 222-005 | 222-305 | — |

| 0.24″–0.31″ (6–8) | 0.94″ | 0.94″ | 222-010 | 222-310 | 222-110 |

| 0.31″–0.47″ (8–12) | 0.94″ | 0.94″ | 222-015 | 222-315 | 222-115 |

| 0.47″–0.79″ (12.0–20.0) | 0.98″ | 0.98″ | 222-020 | 222-320 | 222-120 |

| 0.71″–1.377″ (18.0–35.0) | 0.98″ | 4.53″ | 222-025 | 222-325 | 222-125 |

| 1.37″–2.36″ (35.0–60.0) | 1.10″ | 4.92″ | 222-030 | 222-330 | 222-130 |

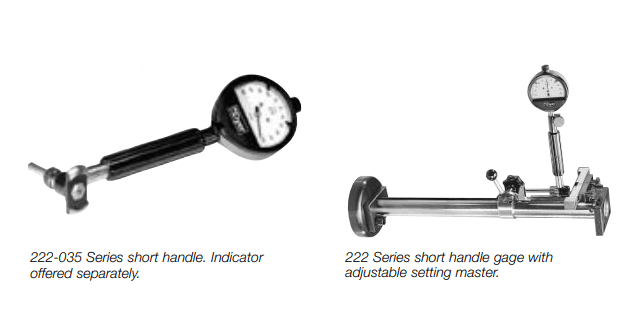

| 1.97″–3.94″ (50.0–100.0) | 1.18″ | 5.51″ | 222-035 | 222-335 | 222-135 |

| 1.97″–5.91″ (50.0–150.0) | 1.18″ | 5.51″ | 222-040 | 222-340 | 222-140 |

| 3.94″–6.30″

(100.0–160.0) |

1.50″ | 6.30″ | 222-055 | 222-355 | 222-155 |

| 6.30″–11.02″ (160.0–290.0) | 1.50″ | 6.30″ | 222-065 | 222-365 | 222-165 |

| 11.02″–16.14″ (280.0–410.0) | 2.17″ | 7.09″ | 222-070 | 222-370 | 222-170 |

| 11.02″–20.08″

(280.0″–510.0″) |

2.17″ | 7.09″ | 222-075 | 222-375 | 222-175 |

| 15.75″–31.50″

(400.0″–800.0″) |

Varies | Varies | 222-080 | 222-380 | — |

1. Order gage model based on diameter range.

1. Order gage model based on diameter range.

2. Order indicator.

3. Order Master.