Maximum Measuring Accuracy

Linear ±0.000040″ (±0.001 mm)

Repeatability <0.000040″ (<0.001 mm)

Gage R & R ≤10% capability when measuring

high tolerance bores.

Please contact Dyer with your application.

Custom Standards and Specials

Dyer also makes special design

measuring sleeves to fit your unique

application. These special design heads

can have:

More contact travel, rough cut/final cut

possibilities

Many unique sleeve profiles

Extra long or short sleeve lengths

2 or 3 point contacts

Special depth stops

Special masters

Special contact shapes, types and sizes

Special coatings

2, 3,or 4 Ø planes and radial axis

CAD Prints and Drawings

Available from Dyer is our “Quick Reference” 8-1/2″ x 11″ reduced drawing of our 240 Series Bore Gages. CAD drawings of our gages on your drawing paper can be done. Contact Dyer Applications Engineering Services.

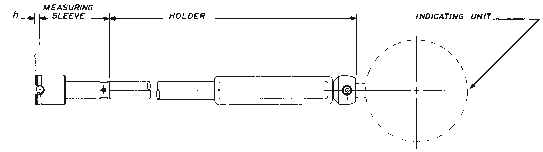

The 240 Series Measuring Sleeves are dedicated gages that are specifically machined to fit a customer’s bore diameter. It is very important to know your part tolerance to make sure the gage has the appropriate range to cover the part specification. On average, the total travel of a gage head is 0.010″ (0.25mm). The ”h” dimension is the distance from the centerline of the measuring contact to the bottom of the measuring sleeve.

This determines how close to the bottom of a bore you can measure. There are basically (3) different standard “h” dimensions. A thru bore “h” dimension is generally 0.400″ (10mm), a blind bore “h” dimension is 0.118″ (3mm) on average, and a super blind “h” dimension is 0.039″ (1mm).

A complete setup includes a measuring sleeve head, a holder, an indicator (mechanical or electronic), and a master ring. If a customer already has an existing holder, indicator, or master, they can adapt the 240 Series Measuring Sleeve directly to it.

We encourage a customer to send us a drawing or sectioned part print of their specific measuring requirement. Our engineering staff will be able to clearly identify the proper measuring sleeve needed to perform the task. A formal quotation can be generated listing all the items needed to make a complete system.

Our standard delivery for diameters between 0.118″ (3mm) and 5.118″ (130mm) is 1 to 2 weeks. Our rush delivery for these same sizes is 1 to 2 days and carries with it a premium charge. We also have an “extended” (or longer delivery) of 6 weeks for these sizes for those customers that are not in a hurry and want a discounted price. Contact Dyer customer service for further details.

240 Series sizes under 0.118″ (3mm) and over 5.118″ (130mm) have a standard delivery of 6 weeks. There are no “rush” or “extended” delivery options for these 240 Series sizes. (Look into the Dyer 440 Series Twin Cross for larger dedicated heads for faster delivery.)

240 Measuring Sleeves

| Sleeve Size Selection | Thru Bores | Blind Hole Bores | Super Blind Hole Bores | ||||

| Inch | mm | Tool Steel h** | Tool Steel | h** | Tool Steel | h** | |

| 0.098–0.117 | 2.5–3.5 | N/A | N/A | 240-035 | “h” DIM’s range between

0.059″ (1.5 mm) and 0.157″ (4 mm) Depends on Sleeve Size |

N/A | N/A |

| 0.118–0.157 | 3.0–4.0 | 240-400 | 0.236

(6 mm) |

240-040 | 240-500 | ||

| 0.158–0.236 | 4.1–6.0 | 240-405 | 240-050 | 240-505 | |||

| 0.240–0.472 | 6.1–12 | 240-410 | All “h”

DIM are 0.400″ (10 mm) |

240-052 | 240-510 | 0.039″ (1mm) | |

| 0.473–0.787 | 12.1–20.0 | 240-415 | 240-055 | 240-515 | |||

| 0.791–1.181 | 20.1–30.0 | 240-420 | 240-060 | 240-520 | “h” DIM is

0.047” (1.2 mm) |

||

| 1.182–1.574 | 30.1–40.0 | 240-425 | 240-065 | 240-525 | |||

| 1.579–2.362 | 40.1–60.0 | 240-430 | 240-070 | 240-530 | |||

| 2.363–3.150 | 60.1–80.0 | 240-435 | 240-075 | 240-535 | |||

| 3.151–3.937 | 80.0–100.0 | 240-440 | 240-080 | 240-540 | |||

| 3.938–4.331 | 100.1–110.0 | 240-445 | 240-085 | 240-545 | |||

| 4.332–4.724 | 110.1–120.0 | 240-450 | 240-090 | 240-550 | |||

| 4.725–5.118 | 120.1–130.0 | 240-455 | 240-095 | 240-555 | |||

| 5.119–5.512 | 130.1–140.0 | 240-460 | 240-100 | 240-560 | |||

| 5.513–5.906 | 140.1–150.0 | 240-465 | 240-105 | 240-565 | |||

| 5.907–6.299 | 150.1–160.0 | 240-470 | 240-110 | 240-570 | |||

| 6.300–6.693 | 160.1–170.0 | 240-475 | 240-115 | 240-575 | |||

| 6.694–7.087 | 170.1–180.0 | 240-480 | 240-120 | 240-580 | |||

| 7.088–7.480 | 180.1–190.0 | 240-485 | 240-125 | 240-585 | |||

| 7.481–7.874 | 190.1–200.0 | 240-490 | 240-130 | 240-590 | |||

| 7.875–9.000 | 200.1–230.0 | 240-616 | INQ. | 240-617 | INQ. | N/A | N/A |