Fast, accurate, repeatable bore gaging

Speed gaging times

Gage multiple dimensions with one gage

Automatic calculations

Absolute numbers

IP/OP to computer and machine

SPC data

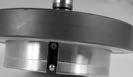

Special Sleeves — 2 sets of contacts in 1 plane

Gaging Application

Measure one bore diameter and out-of-round at specific depth with one gage and with no rotation of the gage in the bore.

Measuring Sleeve Design

Two (2) sets of floating contacts at 90° to each other, in one line and at one depth location.

Gage System Solution Configurations

1. 240 Special Sleeve

One depth stop, two handles, two electronic indicators, one ring gage set master per diameter.

2. 240 Special Sleeve

One depth stop, two handles, two digital electronic pencil probes, one digital readout that does calculations automatically, one ring gage set master per diameter.

3. Special All-Electronic Sleeves

Contact Dyer. One depth stop, two handles, one digital readout, one ring gage set master per diameter.

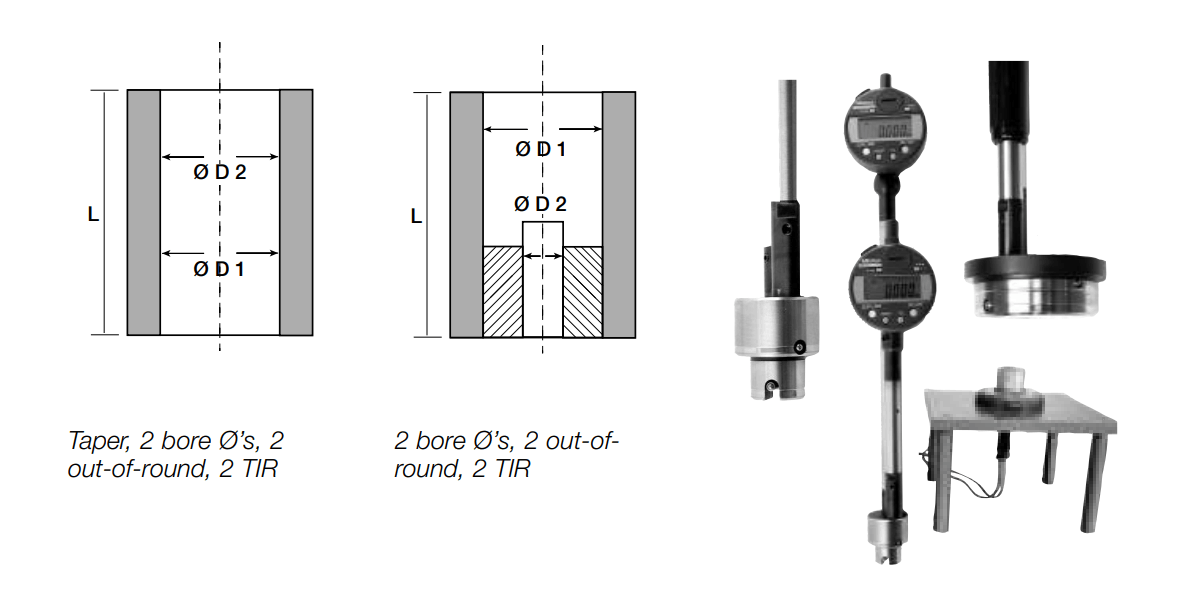

Special Sleeves — 2 sets of contacts in 2 planes

Gaging Application

Measure two bore diameters at two depth locations for diameter, taper, out-of-round, TIR, step or thru bore applications.

Measuring Sleeve Design

Two (2) sets of floating contacts at one or two radial positions, at two depth locations.

Gage System Solution Configuration

1. 240 Special Sleeve

One depth stop, two handles, two electronic indicators, one ring gage set master per diameter.

2. 240 Special Sleeve

One depth stop, two handles, two digital electronic pencil probes, one digital readout that does calculations automatically, one ring gage set master per diameter.

3. Special All-Electronic Sleeves

Contact Dyer. One depth stop, two handles, one digital readout that does calculations automatically, one ring gage set master per diameter.