Maximum Measuring Accuracy

Linear ≤ ±0.000040″ (±0.001 mm)

Repeatability ≤0.000020″ (<0.0005 mm)

Gage R & R ≤10% capability when measuring

high tolerance applications. Contact Dyer with your specific requirements.

Fast, Accurate and Repeatable Measurements

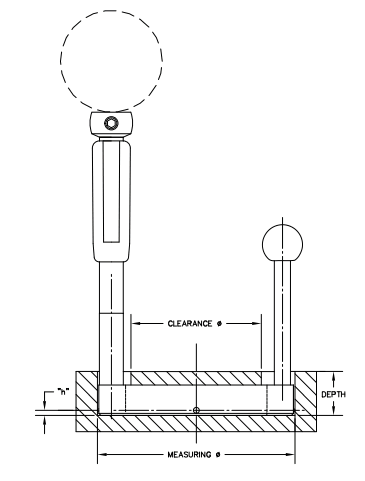

Dyer’s 282 Series Dedicated ID Bore Gage is used to measure a variety of ID diameters, but mostly built for shallow hard-to-reach ID diameters that have a recessed OD hub obstruction in the way.

These rugged and dependable 24-7 bore gages are dedicated gages that are custom made to specific part requirements. They are fast and easy to use. Send Dyer your application and we can construct a model to meet your needs.

The gage performs very well when conducting Gage R&R studies. A 10% R&R can be attained even in close tolerance applications for both small and large bores.

The “h” dimension is the distance from the centerline of the measuring contact to the bottom of the gage. There is no “standard” contact height position. We can measure as close as 0.039″ (1mm) to the bottom of a part. Nevertheless, we will always position the gage contacts in the best location for the job.

Carbide ball contacts are standard, but other materials are available upon request.

This gage utilizes three fixed contacts and one moveable contact in order to measure the desired diameter around the obstruction features of the part.

282 Series custom measuring gages range between 1.5″ (38mm) to 20″ (500mm). Send Dyer your application and receive your unique quotation that will solve your measuring problem.

Dyer is your “one-stop” system supplier.

We can package the measuring head, holder, indicator, and setting master in a single case. Any indicator may be used with this system. Every gage is fully tested for function and accuracy before shipping.