Maximum Measuring Accuracy

Linear ≤ ±0.000040″ (±0.001 mm)

Repeatability ≤ 0.000020″ (< 0.0005 mm)

Gage R & R ≤10% measuring close tolerance parts.

Notable Features

Accuracy and large range.

Select any carbide ball size. Many standard and custom balls in stock.

Carbide ball contacts thread on measuring head.

Customized standards. Contact Dyer office.

Automotive Application

Gear pitch diameter of transmission and drive shaft components.

Chart A. 290 Series Models and Specifications

| Rang | e | Maximum

Diameter Balls1 |

Maximum

Travel/Contact |

Order No. |

| Inch | mm | |||

| 0.315–0.472 | 8–12 | 0.059 | ±0.010 | 290-005** |

| 0.472 –0.866 | 12–22 | 0.157 | ±0.011 | 290-010 |

| 0.866–2.165 | 22–55 | 0.276 | ±0.019 | 290-015 |

| 2.165–9.84 | 55–250 | 0.276 | ±0.027 | 290-020 |

| 3.397–20.079 | 100–510 | 0.276 | ±0.027 | 290-030 |

**Small ranges require fixed contact points for each measurement size.

1 Large ball sizes available. Contact Dyer with your application.

Chart B. 290 Series Threaded Carbide Ball Contacts*

| Order No. (Set) | For Gage Model | Thread Size |

| 290-105** | 290-005 | M 1.6 |

| 290-110 | 290-010 | M 1.6 |

| 290-115 | 290-015 | M 2.5 |

| 290-120 | 290-020 | M 4 |

| 290-130 | 290-030 | M 4 |

* You must specify carbide ball size when ordering.

** Small ranges require fixed contact points for each measurement size.

How to order

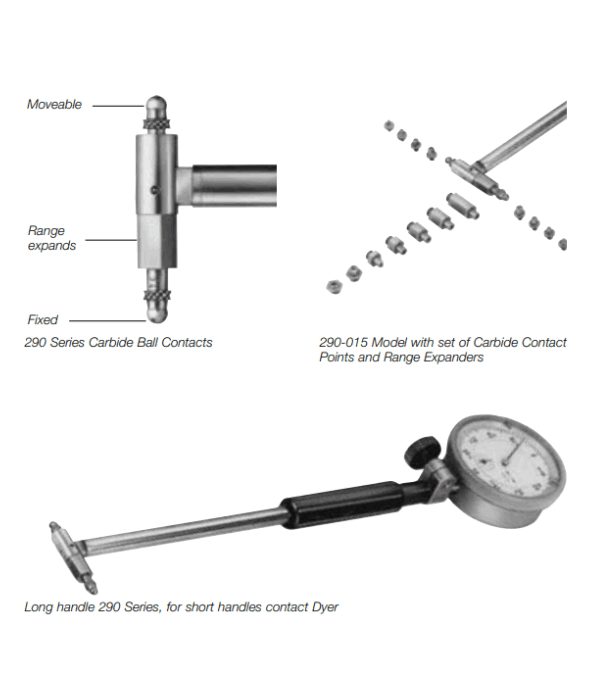

Long handle 290 Series, for short handles contact Dyer