Maximum Measuring Accuracy

Linear ± 0.002″ (0.050 mm)

Repeatability ± 0.001″ (0.025 mm)

Gage R & R capable

Notable Features

Fast, accurate, repeatable.

Light weight.

SPC output for USB or Mitutoyo devices. Cables offered separately.

Absolute and Relative modes with Min, Max and Hold programs.

Tolerance limit markers with Green/Red LED for visual operator judgement.

Internal memory that holds a maximum of 80 measured values.

Programmable auto shut off for battery savings.

IP 67. Gages are shop rugged.

Analog segment (fan) display.

Keypad lock.

Wireless data option. Contact us with your requirement.

652 Series Models and Specifications

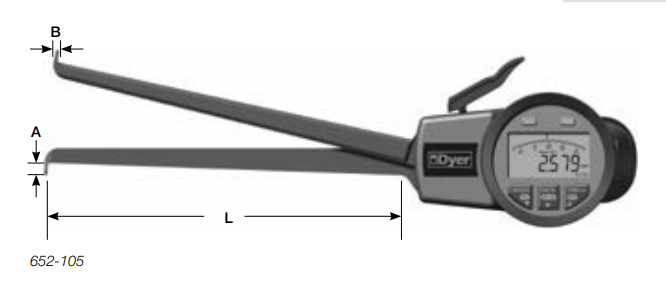

| Application Range | Measuring

Depth L |

Groove

Depth A |

Groove

Width B |

Graduation | Carbide Ball Diameter | Order

Number |

| 0.59″–2.55″

15–65 mm |

7.4″

188 mm |

0.236″ 6.0 mm | 0.079″ 2.0 mm | 0.001″ 0.020 mm | 0.059″

1.5 mm |

652-105 |

| 1.57″–3.54″

40–90 mm |

7.5″

192 mm |

0.33″ 8.5 mm | 0.098″ 2.5 mm | 0.001″ 0.020 mm | 0.079″

2.0 mm |

652-106 |

| 2.75″–4.72″ 70–120 mm | 7.5″

192 mm |

0.33″ 8.5 mm | 0.098″ 2.5 mm | 0.001″ 0.020 mm | 0.079″ 2.0 mm | 652-108 |

| 3.93″–5.90″ 100–150 mm | 7.5″

192 mm |

0.33″ 8.5 mm | 0.098″ 2.5 mm | 0.001″ 0.020 mm | 0.079″ 2.0 mm | 652-110 |

| 5.11″–7.08″ 130–180 mm | 7.5″

192 mm |

0.33″ 8.5 mm | 0.098″ 2.5 mm | 0.001″ 0.020 mm | 0.079″ 2.0 mm | 652-112 |

| 5.90″–7.87″ 150–200 mm | 7.5″

192 mm |

0.33″ 8.5 mm | 0.098″ 2.5 mm | 0.001″ 0.020 mm | 0.079″ 2.0 mm | 652-114 |

Special Carbide Ball Contacts

The carbide ball sizes shown at right are in stock for immediate delivery. We also offer different types of material, i.e., chrome, ruby, ceramic, teflon. Additional customized sizes are available. Contact us with your application requirements.

Carbide Ball Contacts

| Inch | mm |

| 0.031 = 1/32 | 0.5 |

| 0.063 = 1/16 | 1.0 |

| 0.078 = 5/64 | 1.5 |

| 0.098 = 3/32 | 2.0 |

| 0.125 = 1/8 | 2.5 |

| 0.156 = 5/32 | 3.0 |

| 0.188 = 3/16 | 3.5 |

| 0.250 = 1/4 | 4.5 |

| 0.312 = 5/16 | 5.0 |

| 0.438 = 7/16 | 5.5 |

| 0.500 = 1/2 | 6.0 |

| 0.625 = 5/8 | 7.0 |