The Highest Accuracy and Repeatability

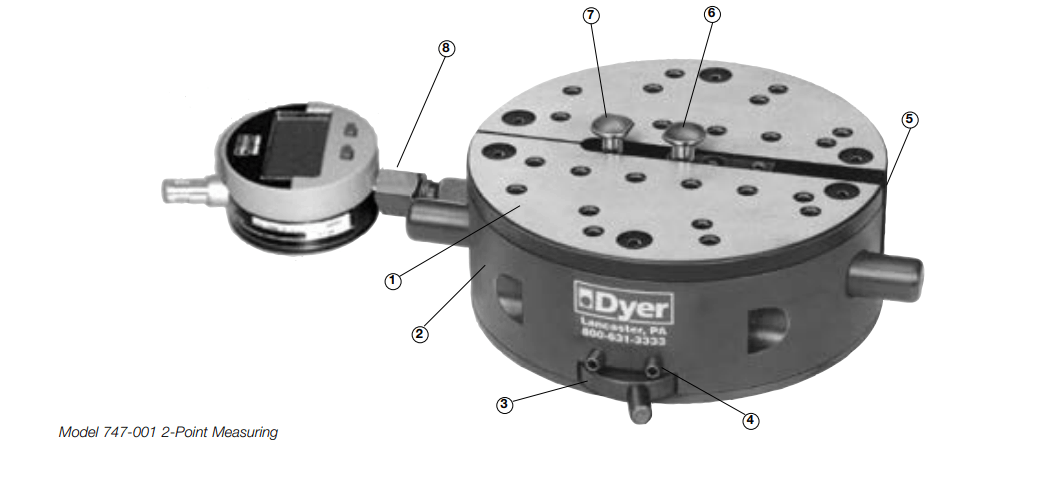

Dyer’s 747 Series is a high-precision measuring table based on a precise linear movement of the moveable contact point. A single unit offers a choice of 2-point measuring or 3-point measuring. The gage can be set up as a “hands off” gage, where the operator places the part on the table and releases the measuring contact. There is no operator error and the system will provide Gage R & R capable measurements. A wide range of gaging options makes this gage Dyer’s most flexible in many measuring applications, such as thin walls, plastics and hard to reach locations on metal parts.

747 Series ID-OD Measuring Tables Design Benefits

These gages are true value leaders and gage most measuring applications.

Notable Features

Armoloy coating on all tables is standard.

ID-OD applications.

High accuracy and set-up flexibility.

Fast, accurate measurements.

Gage R & R capable.

Large range.

Adjustable contact pressure.

Contact point flexibility, use all types of indicators.

Shop-rugged, 24/7.

How to place an order

a. Select the table model you require.

b. Choose electronic or mechanical indication.

c. If you need additional contacts, ring masters or part fixture design setup, contact Dyer Gage.

Special Part Fixturing

We can recommend part fixturing and setup. Contact Dyer Application Engineering with your requirements.

747 Series Models and Specifications

| ID Range | OD Range | Contact Travel | Table Dimensions | Weight | Model

Number |

| Standard

0.345″–7.480″ 9–190 mm |

Standard 0–6.630″

0–160 mm |

0.800″ 20mm |

Ø x Height 5.01″ x 2.4″ 150 mm x 60 mm |

7.72 lbs 3.5 kg |

747-001 747-002 |

| Standard

0.709″–5.118″ 18–130 mm |

Standard

0–4.724″ 0–120 mm |

0.800″ 20mm |

3rd contact stop at 45°

Ø x Height 6.89″ x 3.35″ 175 mm x 85 mm |

11.22 lbs 5.1 kg |

45° Stop

747-004 |

| Standard

0.709″–3.150″ 18–80 mm |

Standard

0–2.362″ 0–60 mm |

0.800″ 20mm |

3rd contact stop at 90° Ø x Height 6.89″ x 3.35″ 175 mm x 85 mm |

11.22 lbs 5.1 kg |

90° Stop

747-005 |

| Standard

0.590″–14.96″ 15–380 mm |

Standard

0–13.78″ 0–350 mm |

0.800″ 20mm |

Ø x Height 11.81″ x 3.35″ 300 mm x 85 mm |

43 lbs 19.5 kg |

747-003 |

| Standard

0.345″–13.000″ 9–330 mm |

Standard

0–11.810″ 0–300 mm |

0.800″ 20mm |

L x W x H 12.8″ x 6.9″ x 2.4″ 325 mm x 175 mm x 60 mm |

19.6 lbs |

747-000 |